Routing laser using laser fiber

When routing laser energy though laser fiber, make sure the delivery fiber does not exceed its minimum bend radius (usually around 6 inches, or 150mm) because bending a fiber beyond this limit may overstress the fiber, leading to potential power losses or in the worst case, a broken fiber.

It is rare for a fiber to fail, but it is nonetheless serious when such a situation occur. The potential can be prevented by equipping the system with fiber breakage detection, which can sense when the fiber has been damaged. The more advanced detection systems test the fiber prior to firing of the laser. Best working practice is to route the fiber above ground, not touching the floor between the laser and workstation to avoid the possibility of crushing the fiber, then coil and hang excess fiber length at the workstation. If the focus head will be moving in the case of a robotic arm, give sufficient slack, and again make sure the fiber’s connection to the focus head avoids exceeding the minimum bend radius.

Routing laser

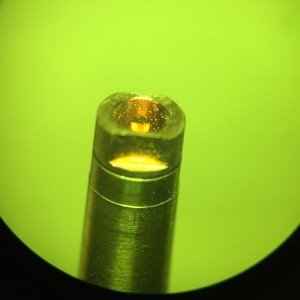

Most system integrators will usually provide the correct space within the workstation, but it is important to note that cable management from the workstation to the laser is the responsibility of the end user. It is also worth noting that increasing the length of the fiber does not result in a significant decrease in delivered power as the delivery of the laser through the fiber is very efficient. The main power losses occur at the fiber’s entry and exit from the laser. It is important to keep the entry and exit point clean, free from debries, dust, oil and solvants.

Please read our post on maintenance of optics for some tips on how to increase lifespan of your optics by regular maintenance.

| Allowable bending radius | |

| 200 | 100 |

| 300 | 100 |

| 400 | 100 |

| 600 | 150 |

| 800 | 200 |

| 1000 | 250 |

| 1200 | 300 |

Laser

Laser