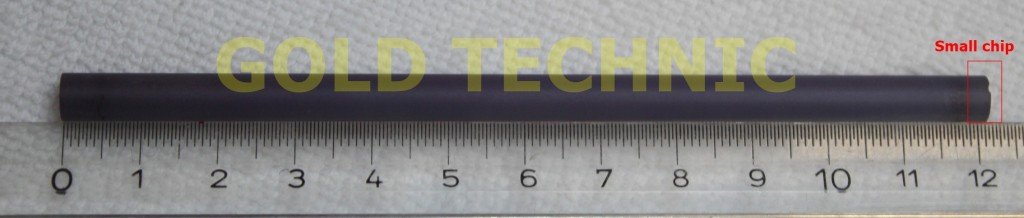

Alexandrite rod for repair recoat refurbish

Alexandrite rods are used in Alexandrite lasers. It is a chromium-doped solid-state lasers based on the crystalline gain medium alexandrite, which is Cr3+:BeAl2O4. There are natural alexandrite gem stones, but material for laser crystals is artificially produced and grown in monocrystalline form with high crystal quality, using a modified Czochralski growth method. Among solid-state laser crystals, Alexandrite is the most suitable for a wide range of medical applications such as the lasing wavelength and tunability.

Alexandrite lasers is one of the most robust solid-state laser materials available with a thermal shock resistance five-times that of Nd:YAG.

Alexandrite’s combination of properties offer application in Medical / Aesthetic and other fields, in such areas as: dermatology, lithotripsy, dental, spectrosocopy, atmospheric lidar, testing of fiber optics and photodetectors, materials processing, pumping of dye lasers, non-linear optics studies and annealing of semiconductors.

Alexandrite rod Applications

Typical applications include laser-assisted hair removal, leg vein reduction and tatoos removal: as matter of fact Alexandrite is becoming the material of choice for a variety of aesthetic dermatology.

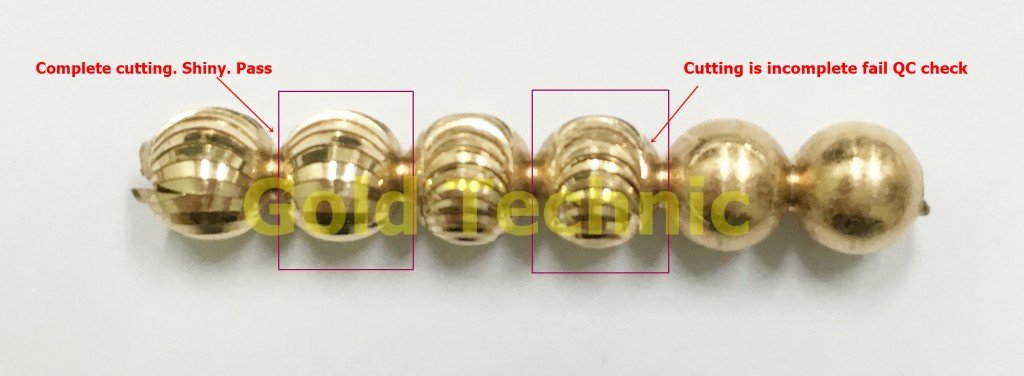

We are also providing servicing of Alexandrite rod of all sizes. Recently serviced rod for our customer using the Candela GentleLaser Laser Machine lowering their cost of operations. There are many reasons for Alexandrite rod breakdown in your laser machine. The rod may be broken due to mishandling or excessive water pressure build up or a leak in the laser chamber. Dust particles that has entered the chamber, the optics, or the rod itself can cause the laser head rod to burn entirely over time.

After repair was done, our customer was able to get their Alexandrite rod working at a fraction of the price for a new replacement. The performance of the machine was as good as before.

The above rod can be used in Candela® GentleLaser series of machines

- GentleLase

- GentleLase plus

- GentleLase mini MGL

- Gentle MAX GMAX

- GentleLase Pro

We can also repair other models and sizes of Alexandrite rod.

Alexandrite rods Applications

AB Laser inc®, Baase®l Lasertechnik®, Cynosure®, Wavelength® and many more

Please feel free to email us or contact us at sales@goldtechnic.com for more detailed quote of your repair job.