Precision cut gold ball chain by CNC diamond tool cutting machine

Precision diamond cutting tool Research and Developemnt

Precision diamond cutting tool can be used to cut metals such as gold, silver, copper and brass. In jewellery manufacturing, gold and silver are most commonly used. It is important to fine tune diamond tools when working on CNC cutting machine to reduce machine downtime and wear and tear of the tools. Maintenance Policy and Procedures of CNC machines and precision diamond tools are also very important in prolonging lifespan of diamond tools. We will elaborate more on recommendations on maintenance policies in our next contribution.

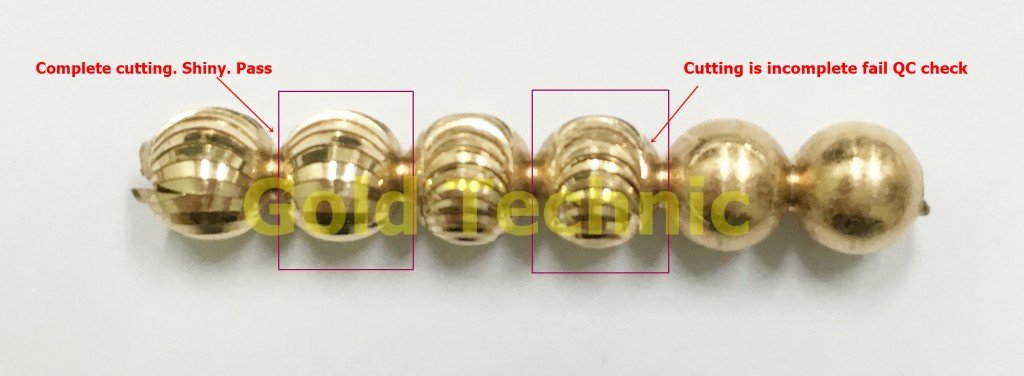

We help our customer troubleshoot to get the perfect precision diamond cut on the ball chain machine. The above picture shows row of ball chain that was cut by a precision diamond cutting tool that failed the cutting test on the first trial run because it cannot produce the perfect crescent/ moon cut on the ball chain. The moon cut was too small and cannot cover the whole surface of the ball. That has resulted in a dull and unfinished ball.

Surface finish on a ball chain can be compared to reflective qualities of diamond when cut in different shape. For example Round brilliant cut, Marquise cut, Oval cut and Princess cut. In this case, it is widely known in the market that the Round brilliant cut brings out the most shine in a diamond. Similarly, with our experience in producing diamond tools, we can recommend the ideal profile to produce the best cut on ball chains.

Precision diamond cutting tool Diagnosis

After our study of the initial problem, the production team redesign the tool and test on the balls again. Finally we could achieve the perfect cut. We complete the development process in about 6-8 weeks and customer was very satisfied with the performance. This shows how important it is to engage the right company to propose the best solutions for all your diamond cutting needs.

Do give us a call or email us for more solutions on precision diamond cutting tools. We will be updating our blog periodically.