Since the core of fiber optic cable is silica (glass), proper Laser Fiber Handling procedures need to be observed at all times. We have put together a list of the most important Laser fiber handling procedures. The intent of these procedures is to maintain optimum performance of the laser fiber, minimum loss and most of all, a safe working environment.

- Protect the exposed Laser fiber end from coming in contact with all surfaces. Always use the protective cap.

- The use of high-pressured compressed air should NOT be used at all times.

- Clean the connector with alcohol each time it is inserted into an adapter . Make sure that the adaptor is clean before inserting the Laser Fiber

- The minimum bend radius of the fiber must be maintained. Please refer to our article on minimum bend radius for more information.

- If a fiber is fastened using tie wraps, do not over tighten.

- Unused connectors should always be covered or capped. Always keep the end of the fiber pointed down to prevent any falling debris from landing on the end of the fiber. Never touch the end of the fiber or blow on it with your mouth. Saliva particles or dust might stick onto the fiber ends resulting is more damage.

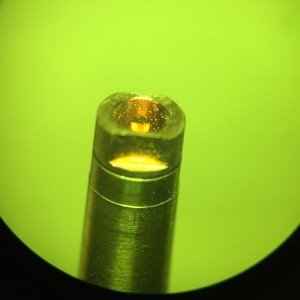

- When holding the connector, hold only the collar and main body of the connector. Never touch the brass part or the tip of the fiber optic cable.

- Use fiber-cleaning materials only once. Only Lint free lens/optic paper and Powder Free latex gloves should be used.

- For safety, never inspect a fiber optic cable while looking directly into the fiber end while connected to a laser source. Always disconnect the laser fiber from the laser source and keep the un used side capped before conducting any inspection. Eye damage may occur if you stare directly at an active fiber end.